Quality - Made in Germany

Quality - Responsibility - Passion!

Hamberger has been producing in the Rosenheim region for over 150 years and has always remained true to its location. Even with products of the brand HARO experience and expertise is a key factor for top quality. Because only those who are passionate about their profession can maintain a consistently high level of responsibility and quality.

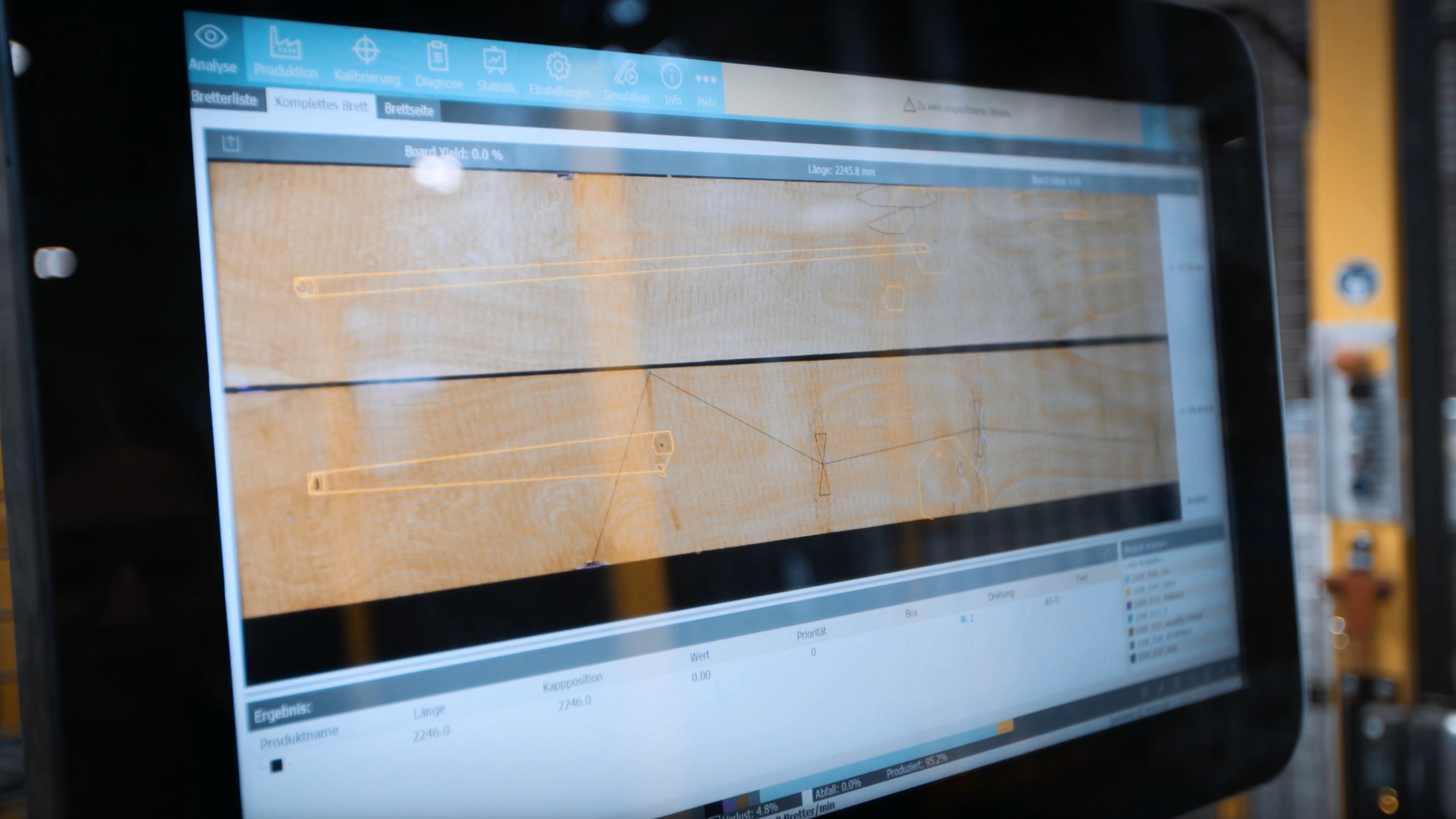

With HARO it is above all the knowledge of its long-standing employees and the experience gained from 75 years of parquet production that makes every single plank a masterpiece. This cannot be replaced by AI, but it can be optimised by state-of-the-art machines and software. This is one of the reasons why Hamberger has invested several million euros in production and is demonstrating how parquet is manufactured for the future in Rosenheim.

Investing in the future - Made in Germany

We have dedicated ourselves to the task of producing more than just flooring. We create living spaces that are characterised by the highest quality, sustainable action and a deep passion for environmentally friendly products. This is why Hamberger Flooring continuously invests in Rosenheim to ensure consistently high product quality in the future. The unique combination of artificial intelligence, automated production processes and the extensive expertise and passion of our long-standing employees for wood and high-quality products is key to this.

This combination is only possible in this form in Germany, which is why we consciously continue to focus on this location. Responsibility, passion and quality are deeply rooted in the company's DNA - we are committed to these values in our daily actions and every decision we make. In addition, HARO not only secures jobs and strengthens the regional economy, but also contributes to efficient logistics through short delivery routes, which ensures the rapid availability of products and minimises the ecological footprint.

Parquet production at the highest level

Accompany the raw material wood through the production process

In the film, you can accompany the natural product wood on its way to becoming a parquet plank in all the work steps that are carried out in the factory.

It becomes clear: state-of-the-art machines work precisely and accurately with intelligent software, but the choice of quality and appearance is always made by people in the end. Because wood is a unique living material. It takes the experience of many decades to ultimately create a HARO quality product that meets our own high standards.

Would you like to find out more about us?

If you have any questions about HARO or the Hamberger family business, please contact schreib uns or visit us in Stephanskirchen near Rosenheim.

We look forward to hearing from you and will be happy to answer your questions.